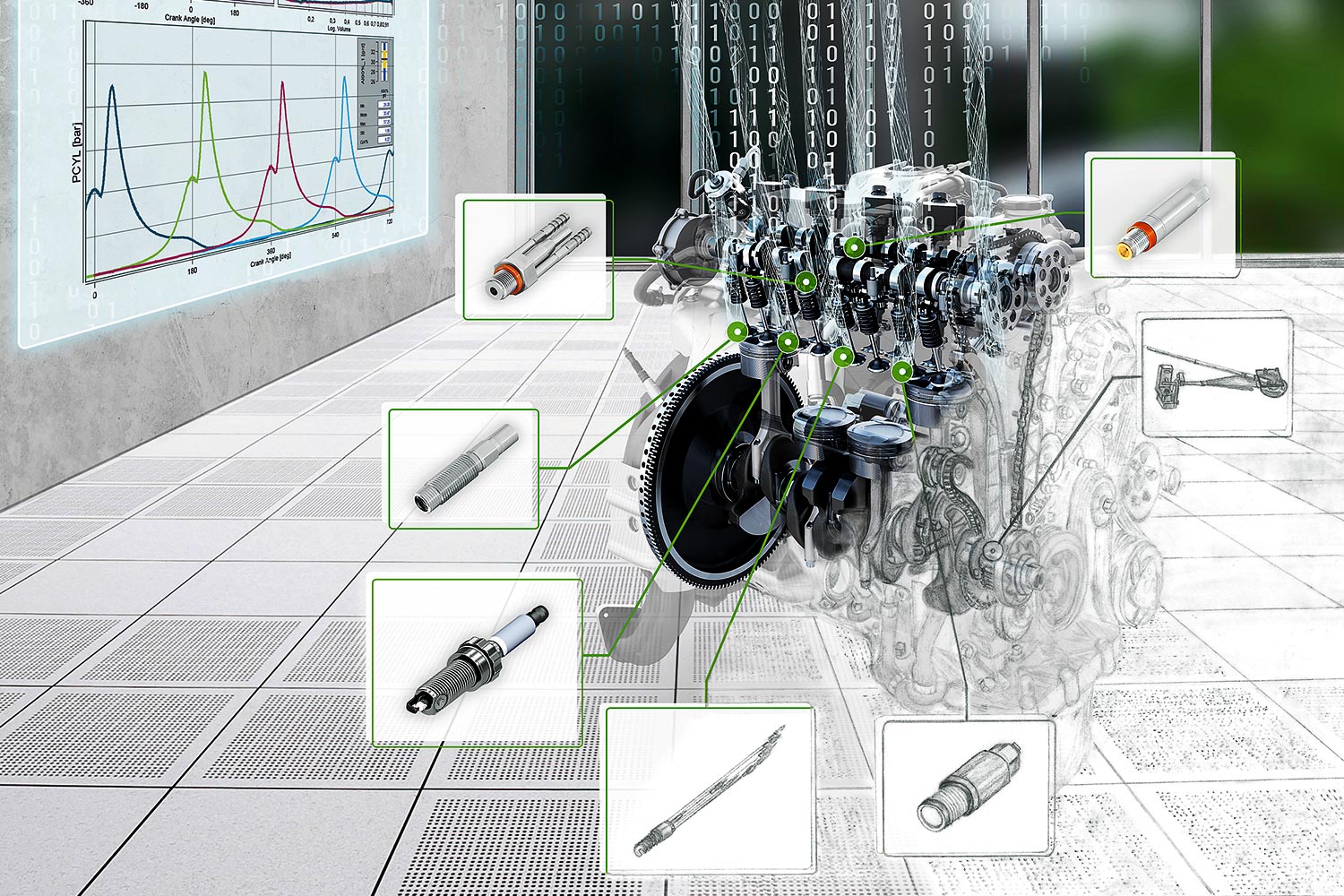

Test Systems and Sensor Technology

Testing until you get a winning race car

Is the car ready for the racetrack, or not? This question is answered in the test phase, making highly representative and reliable test systems all the more important. AVL RACETECH supplies extensive test solutions, instruments and systems, including services and support.

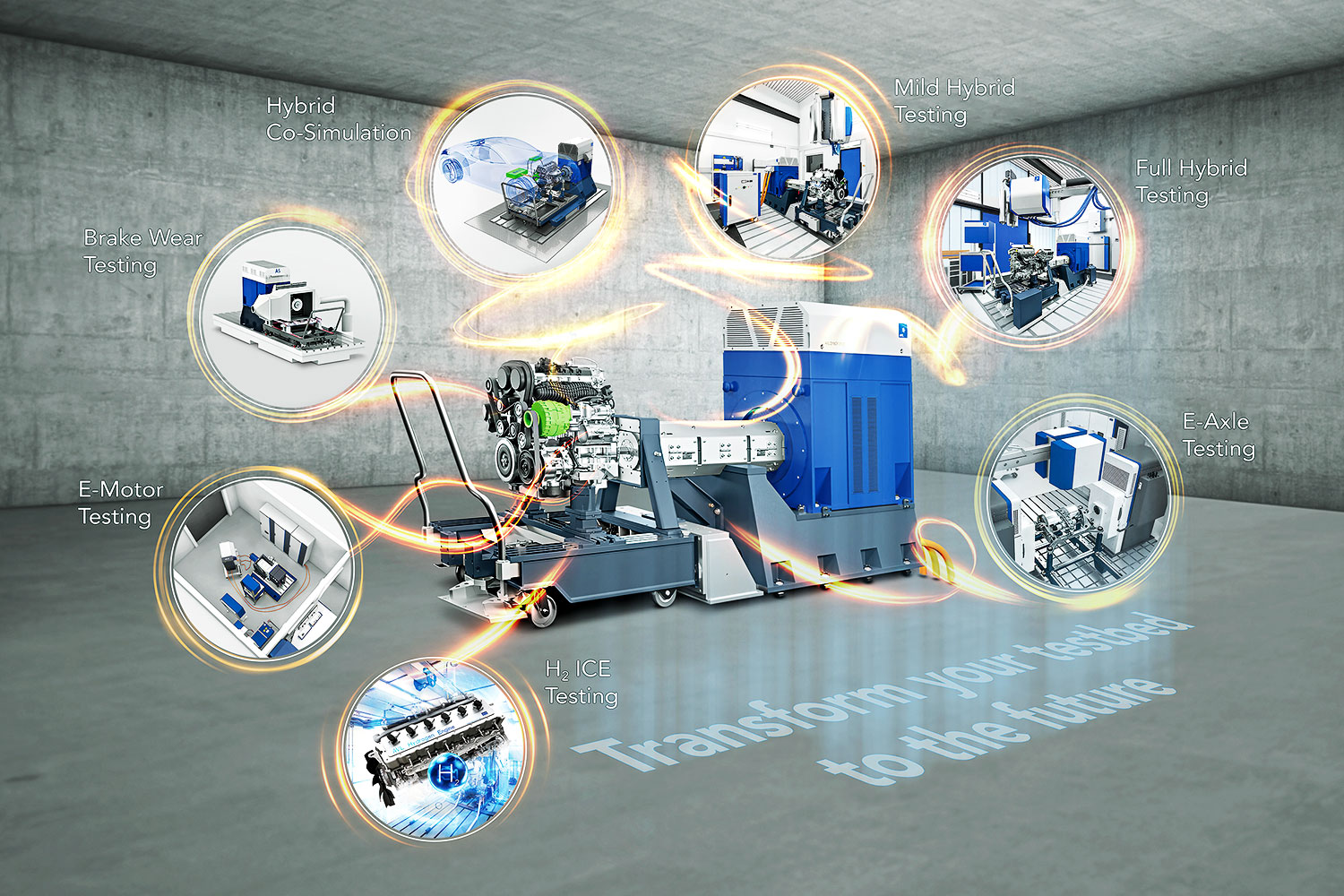

The full AVL portfolio for the motorsport industry includes solutions for:

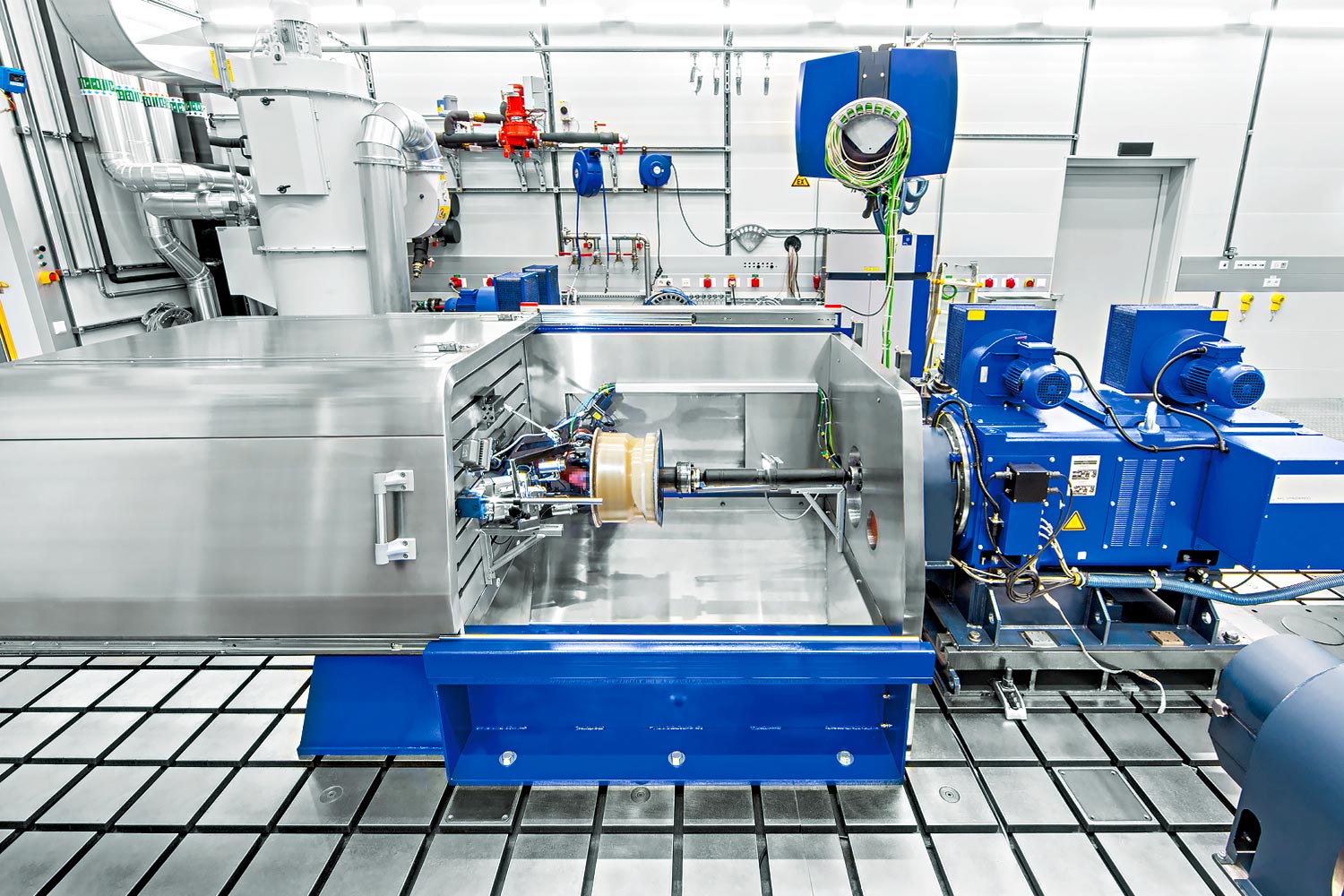

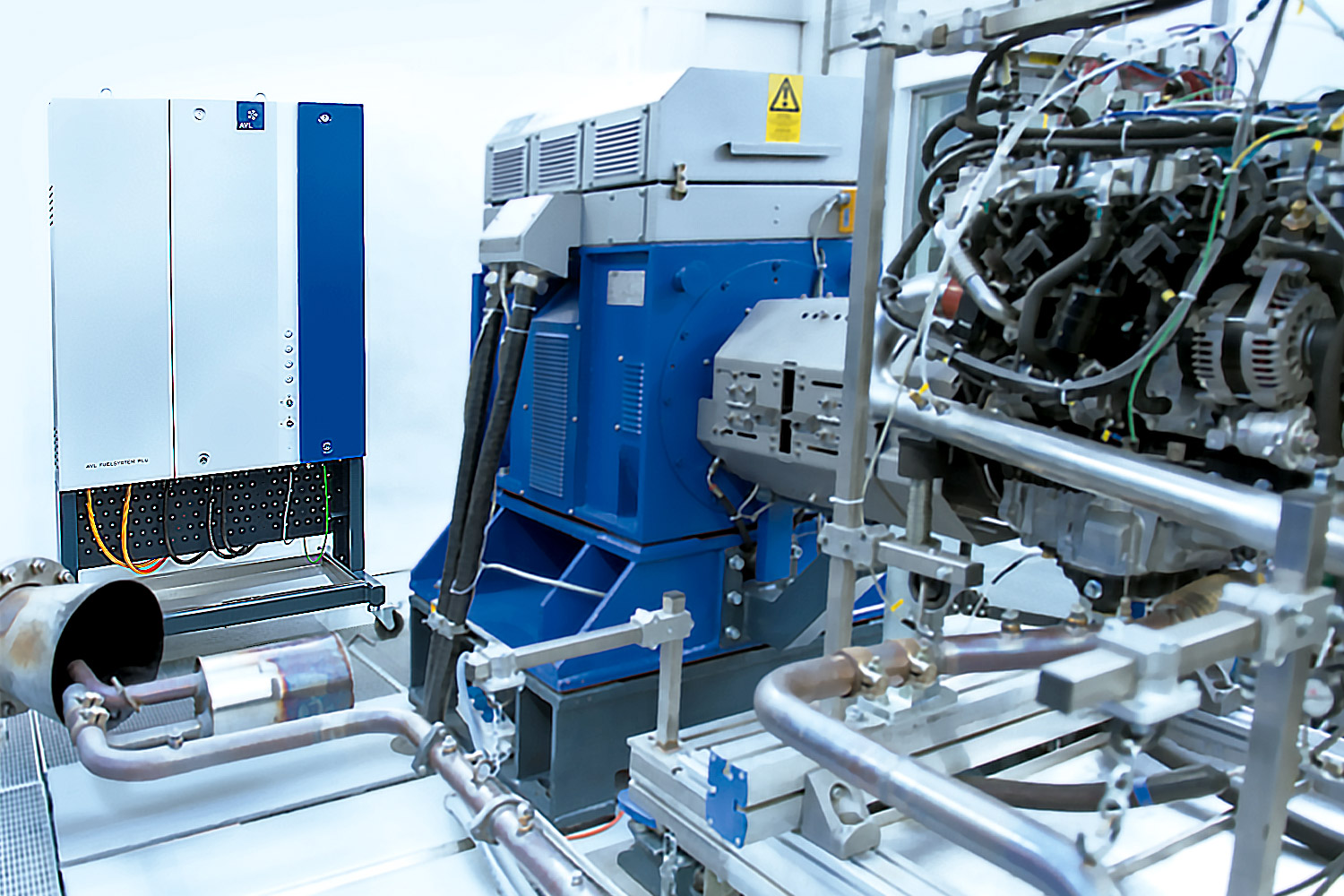

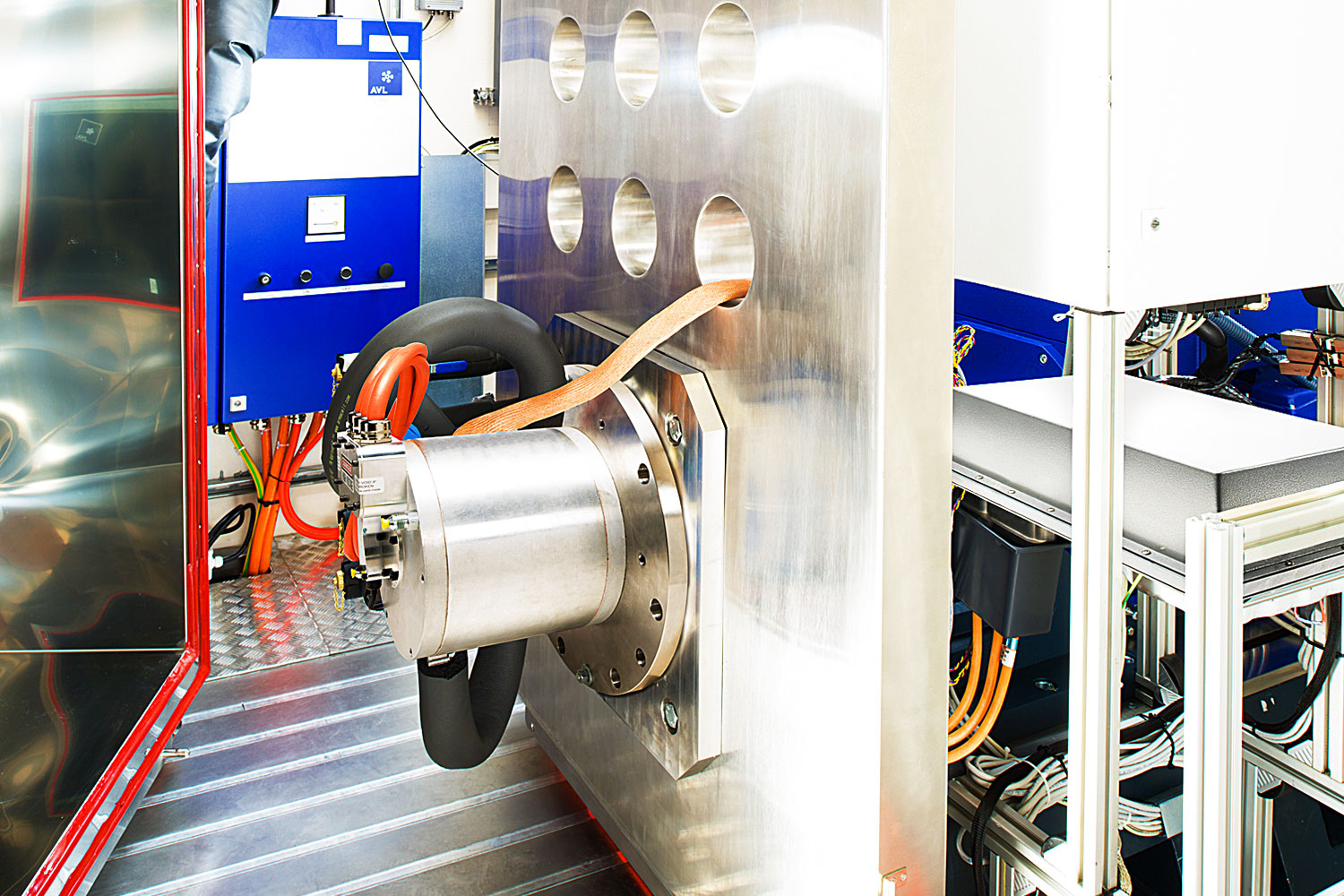

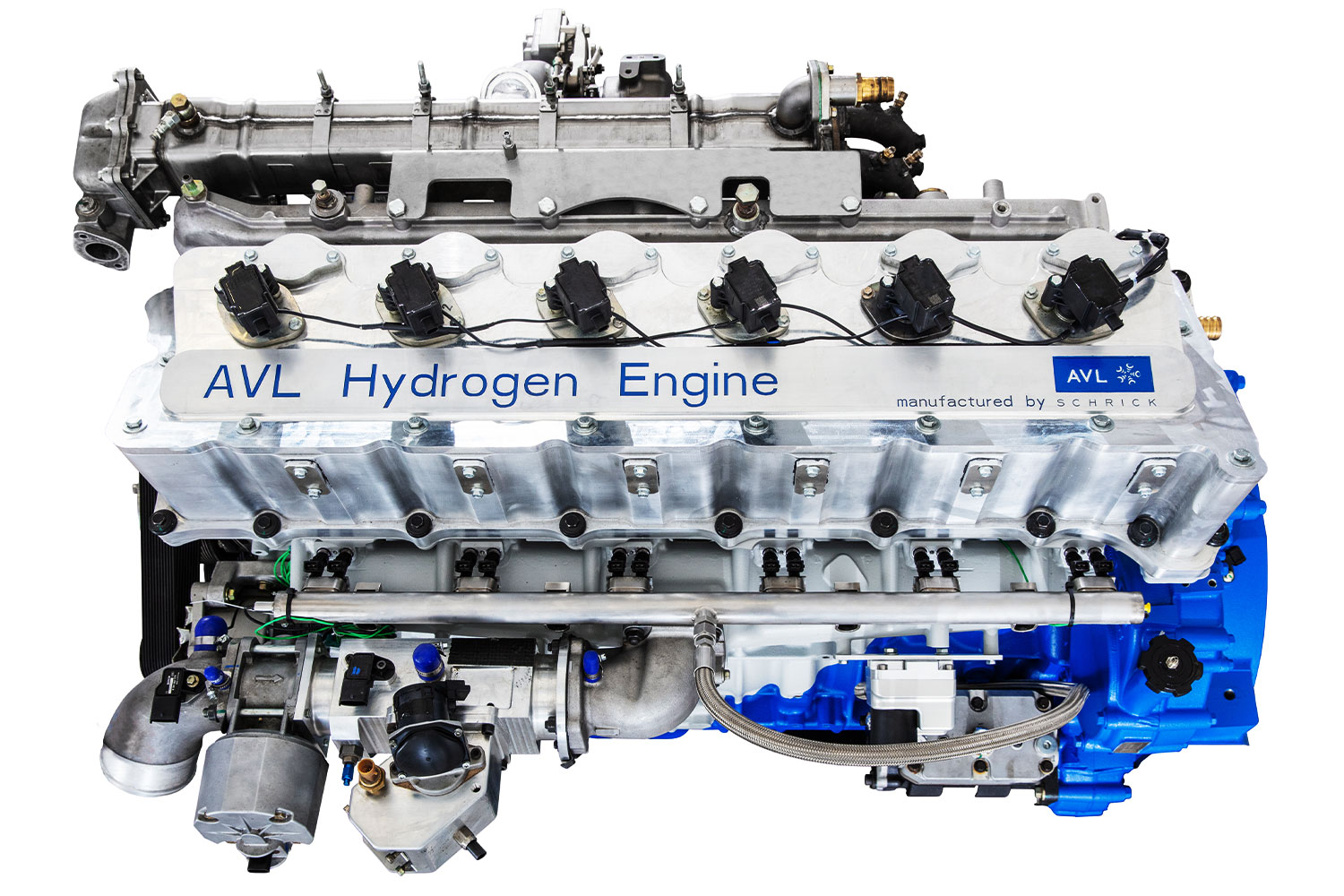

- Engine and propulsion unit

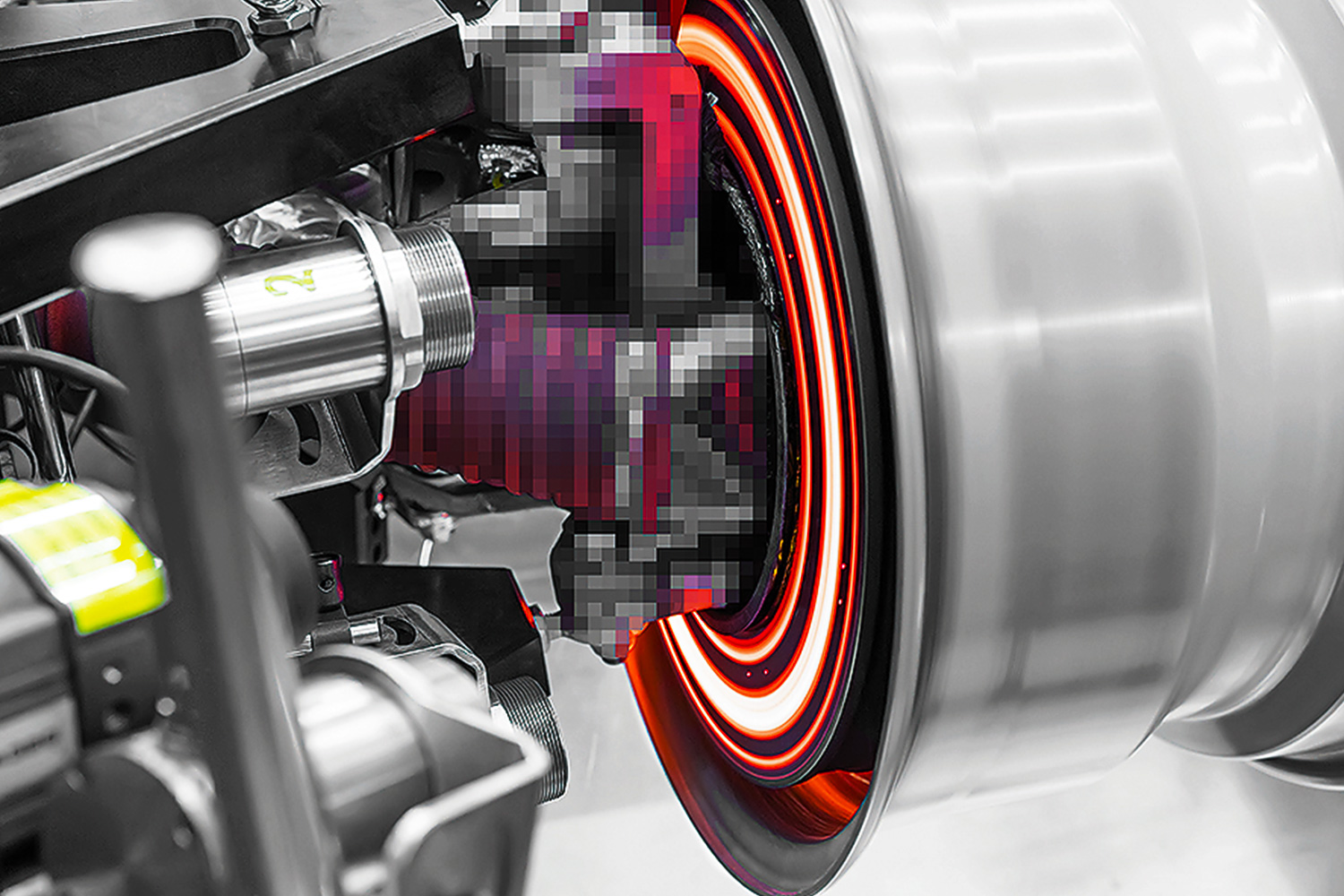

Testbeds, from single-cylinder engines to highly-dynamic racing engines and power units - Transmission

Tools for improving efficiency and optimizing shift times - Propulsion system

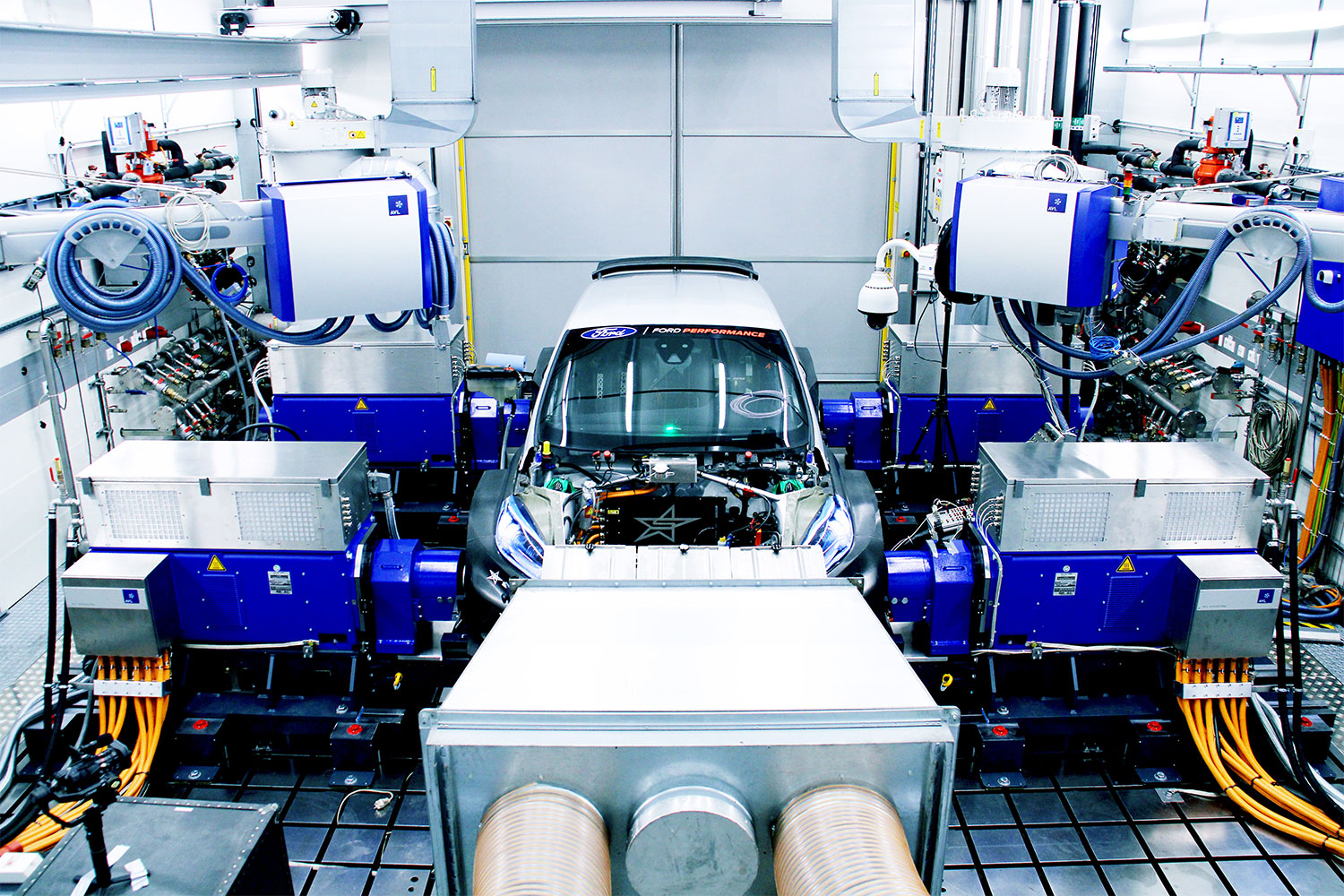

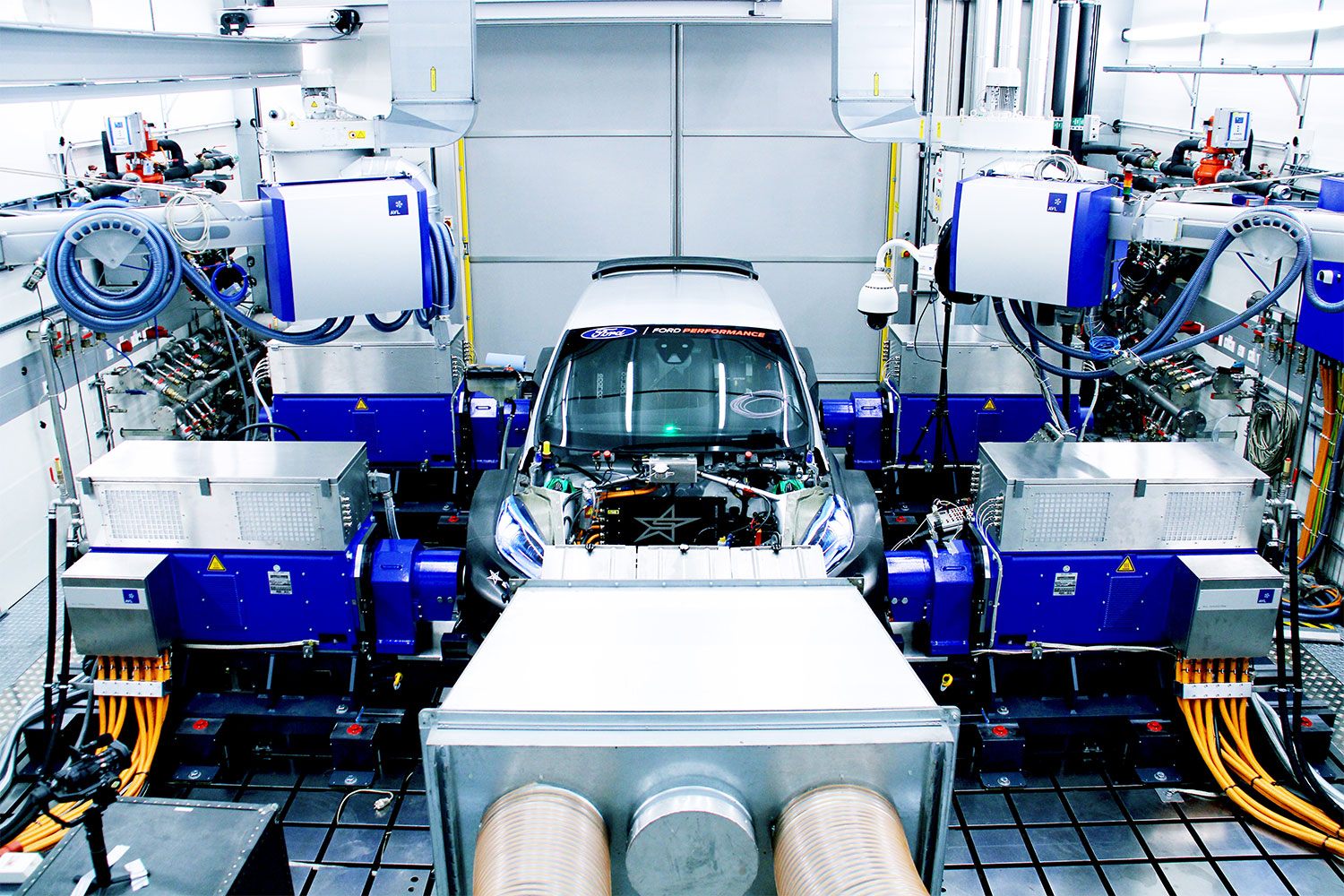

Testbeds for single-axle and four-wheel drive vehicles - Whole vehicle

Realistic test environment away from the racetrack